Thanks to the use of material lifting machines for construction, productivity and safety have greatly improved on construction sites which has led to many changes in the industry over the years. Such advanced devices are now necessary tools that help workers lift and move massive items, work high above the ground, and complete projects in the expected time. People involved in construction such as contractors, engineers, and project managers, should be familiar with every type of lifting equipment and the way it is put to use.

Construction Lifting Technology’s Development

High-quality and dependable techniques are needed to transfer materials between all the floors and areas of a building at modern construction sites. Today’s machinery is now used instead of manual lifting which helps handle much larger ships while keeping safety measures in place. A wide range of construction lifting machines, powered by pulleys up to sophisticated hydraulics, can move very heavy objects with accuracy.

The use of leading technology makes these devices easier and safer for people to manage. For the purpose of lessening the chances of accidents and making lift operations more effective, today’s equipment offers better weight spread, built-in safety technology, and better control methods. Because of these developments, large-scale hoist lift construction projects benefit a lot when safety and schedule are major concerns.

Benefits of Utilizing Hydraulic Lifting Systems

Construction work has been revolutionized by hydraulic lift technology that ensures strong, controlled, and smooth lifting. These systems are better than old mechanical methods because of the way they use pressure fluid to produce the lifting power needed for large objects. Hydraulic systems manage both speed and location precisely which reduces wear and damage to both the machinery and the loads.

As they are dependable, strong, and able to consistently handle many load weights, hydraulic lifting systems are beneficial. Due to their compact size, many hydraulic machines are a great choice for city construction projects where space is not generous. Besides, it is generally less expensive to look after a hydraulic system than a mechanical one which reduces both running expenses and time without operation.

Regional Building Lifting Equipment Considerations

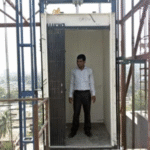

Construction lifting operations have particular opportunities and constraints in urban areas like Mumbai. Specific methods for material handling and lifting operations are needed due to the congested urban setting, space constraints, and strict safety rules. Installations of hydraulic lift Mumbai must maintain peak performance levels while adhering to regional construction norms, safety regulations, and environmental concerns.

Lifting equipment deployment and selection are influenced by major urban regions’ accessibility, infrastructure constraints, and climate. Construction firms working in these settings have to take into account things like noise levels, available space, and integrating lifting systems with the city’s current infrastructure. To guarantee correct installation, upkeep, and adherence to legal standards, the knowledge of regional specialists and service providers becomes essential.

Construction Lifting Safety and Efficiency Innovations

Across the construction industry, the use of sophisticated material lifting machine for construction has greatly raised worker safety requirements. Load monitoring, emergency stops, backup power, and fail-safe brakes are among the many safety systems on modern lifting machinery. As well as ensuring safe and reliable operations, these improvements keep operators and nearby staff safe.

The importance of equipment operator training and certification programs has grown as lifting technology has advanced. Comprehensive safety measures must include appropriate operation methods, regular maintenance schedules, and emergency response plans. In order to detect such problems before they jeopardize operating effectiveness or safety, regular inspections and preventative maintenance plans are helpful.

Conclusion:

Emerging technologies like IoT integration, remote monitoring capabilities, and automated control systems are driving further change in the construction lifting sector. These developments offer useful data for project management and optimization, and they promise to significantly improve lifting operations’ safety, effectiveness, and cost-effectiveness.

Effects from the industry’s efforts to be more eco-friendly and digitized may lead to advanced connectivity, improved energy efficiency, and more eco-friendly technology in material lifting machines for construction. Because building projects require more skill and equipment, investing in advanced lifting gear is now very important for modern construction businesses.